The atomic electric field distribution in 2D WSe2

Research of the working group for nanostructuring | NNP

Most properties of solid materials are fundamentally determined by the atomic-scale electric field and charge density distributions. Crystallographic defects can significantly alter this internal field distribution and thus change the material properties. In this study, the impact of defects on the electric field and charge density distribution of WSe2 is revealed using a new, emerging scanning transmission electron microscopy technique, differential phase contrast (DPC) imaging, combined with comparative density functional theory (DFT) simulations.

Click here for the research report.

Contact person: Julian Sulikowski

Hybrid design as a contribution to sustainability (Full text in German only)

Projects of the Automotive Lightweight Design Group | LiA

Various research projects have demonstrably shown that the combination of different materials to form a hybrid system leads to advantageous component properties. However, a decisive contribution to sustainability can only be guaranteed if the resulting energy requirement during material provision, production and the utilization phase is lower than for comparable components made from homogeneous material systems. Life cycle assessment (LCA) serves as a tool for evaluating the environmental impact of hybrid construction methods.

Click here for the research report.

Contact person: Maximilian Kaiser

Correlation of microstructure and corrosion of additively manufactured aluminium components (Full text in German only)

Due to their good corrosion resistance, the demand for Al alloys from additive manufacturing processes in industrial applications is increasing rapidly. However, recent studies show a crucial dependence of the corrosion resistance on the microstructure of the Al components. By means of nano-additives (SiC and TiC), the microstructure of AlSi10Mg components could be significantly modified, which consequently also affects the corrosion resistance of the components. In this study, the microstructure of the heat-treated components could be correlated with the corrosion properties.

Click here for the research report.

Contact person: Dr. Sabrina Kollmann

Hybrid lightweight construction made easy (Full text in German only)

At the Institute for Lightweight Construction with Hybrid Systems (ILH) at the University of Paderborn, more than 170 scientists are researching novel lightweight construction technologies. As part of the HyOpt project, a team of ILH researchers and industrial companies is dedicated to developing an automated approach for the design and production of hybrid multilayer composites with customised functional properties.

Click here for the research report.

Contact person: Maximilian Kaiser

When it gets damp in the material (Full text in German only)

In close cooperation with the Chair of Technical and Macromolecular Chemistry, the Chair of Plastics Technology Paderborn is researching the macro- and microscopic interrelationships of the degradation reactions and, together with several industrial partners, is developing recommendations for action for material selection and processing conditions.

Click here for the research report.

Contact person: Leon Schäffer

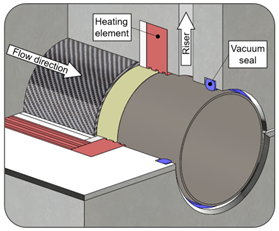

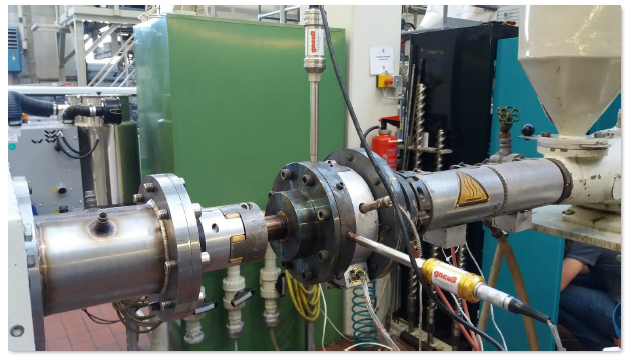

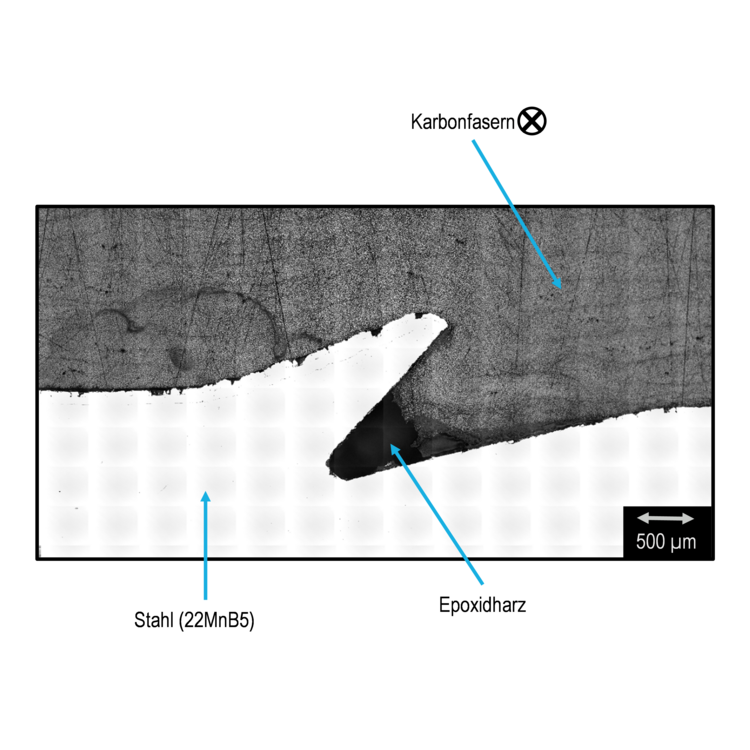

Hot forming process-integrated surface structuring for hybrid components (Full text in German only)

In cooperation with the Institute for Machine Tools and Production Engineering at the Technical University of Braunschweig, scientists at the Institute for Lightweight Construction with Hybrid Systems / Lightweight Construction in the Automobile have developed a process that integrates surface structuring in the press hardening process. The structuring ensures improved bonding of fibre-reinforced plastics to the metallic base component.

Click here for the research report.