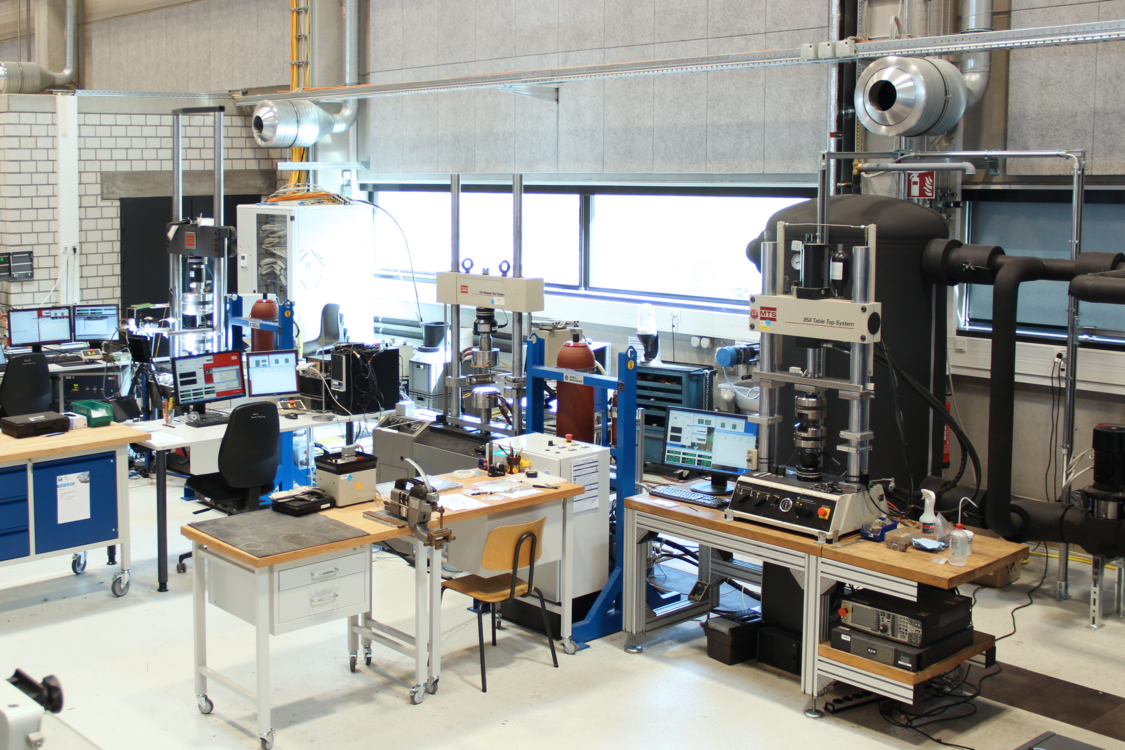

Cupping testing machine < 400° C

Technical specifications

- Nakajima punch Ø 100 mm

- Cupping tests up to 400° C by heating punch and tools

- Various proven lubrication systems to minimise friction at different temperature ranges

- Maximum punch force up to 1000 kN

- Force recording up to 250 kN

- Displacement measuring system for recording the punch displacement

- Inline measurement of strain using optical measuring systems (gom ARAMIS)

Application

- Cupping tests according to DIN EN ISO 12004-2 to determine forming limit curves for different materials, sheet thicknesses and temperature ranges

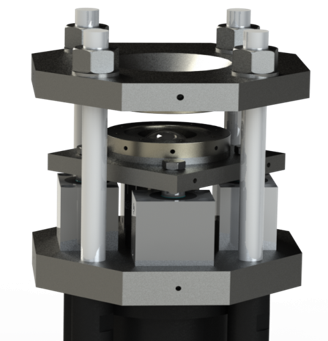

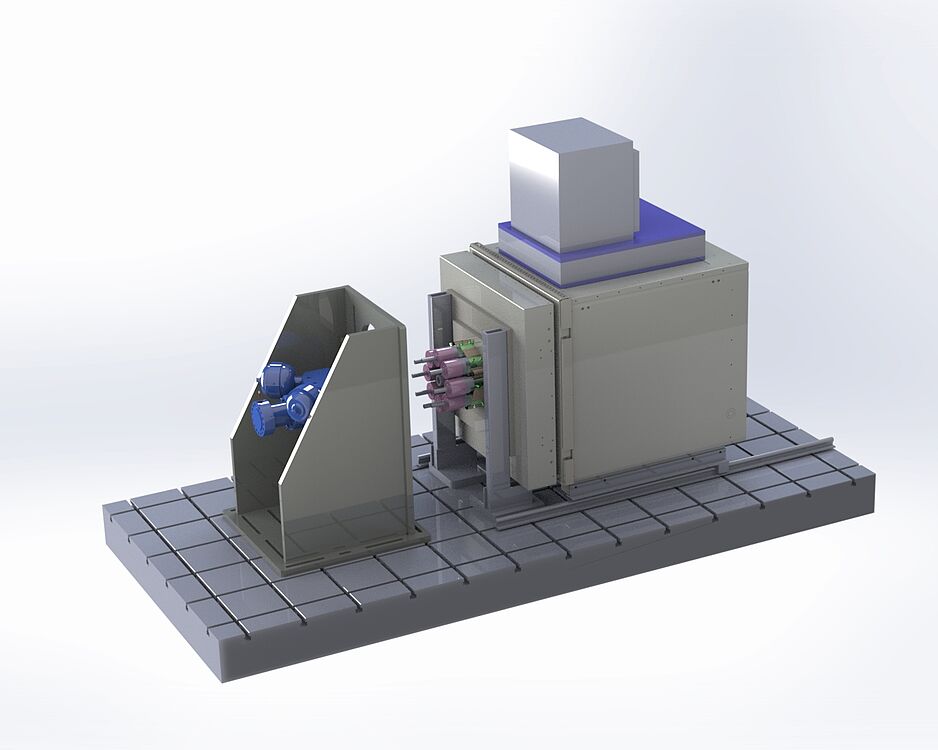

Cupping testing machine > 400° C

Technical specifications

- Nakajima stamp Ø 100 mm

- Cupping tests up to 800° C in isothermal furnace atmosphere

- Sluice system for sample feeding

- Maximum punch force up to 100 kN

- Force recording up to 100 kN

- Displacement measuring system for recording the punch displacement

- Subsequent measurement of strain using optical measuring systems (gom ARGUS)

Application

- Cupping tests according to DIN EN ISO 12004-2 to determine forming limit curves for different materials, sheet thicknesses and temperature ranges

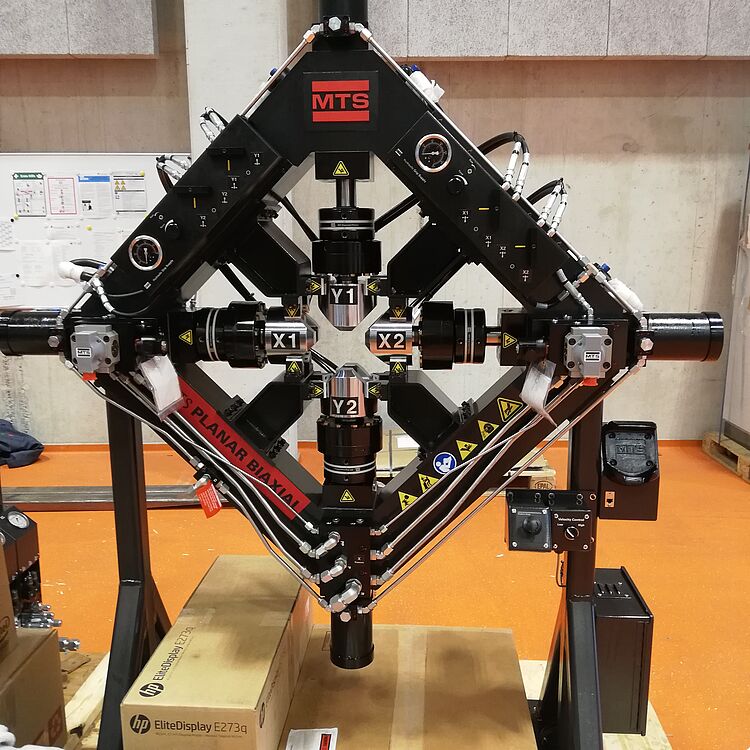

Planar biaxial testing machine

Technical specifications

- 4 actuators of two orthogonal load axes in one plane

- Maximum forces per axis up to 25 kN

- Force recording per axis up to 25 kN

- Centre point control by actuator control

- Displacement measuring system for recording the actuator movements

- Determination of strains with optical measuring systems (gom ARAMIS)

Application

- Multi-axis tensile tests in the plane to determine the isotropic and anisotropic material behaviour of various polymers and fibre-reinforced plastics.