Semi-finished product production & preparation

Semi-finished product processing & component production

- Resin injection plant Tartler GmbH

- Resin injection plant Wolfangel GmbH

- Hydraulic press LaboPress P200S Vogt

- Servo motorised screw press Synchropress GmbH

- Hydraulic press Hessmert

Contact: Maximilian Kaiser

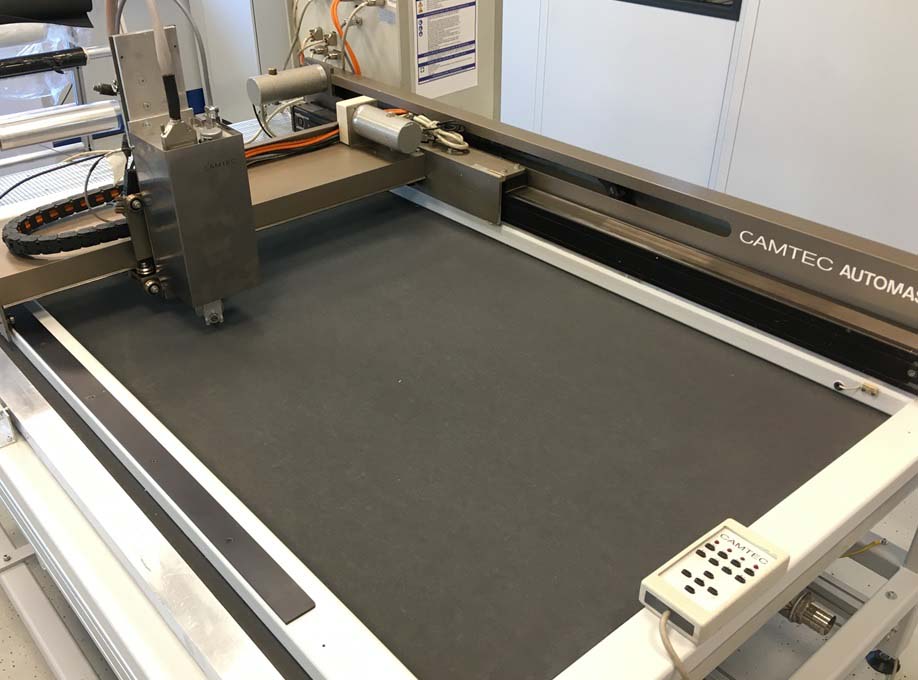

Portal Cutting Machine: CAMTEC AUTOMASK Vario

Technical specifications:

- Manual / Automatic trimming

- Tangentially guided, rotating knife

- Working area: 1,000 mm x 580 mm

- HPGL interface (conversion from e.g. DXF format possible)

- Vacuum table for secure fixing of the material to be cut

Application:

The CAMTEC AUTOMASK Vario gantry cutting machine is used for cutting flat templates as well as dry or pre-impregnated semi-finished fibre products.

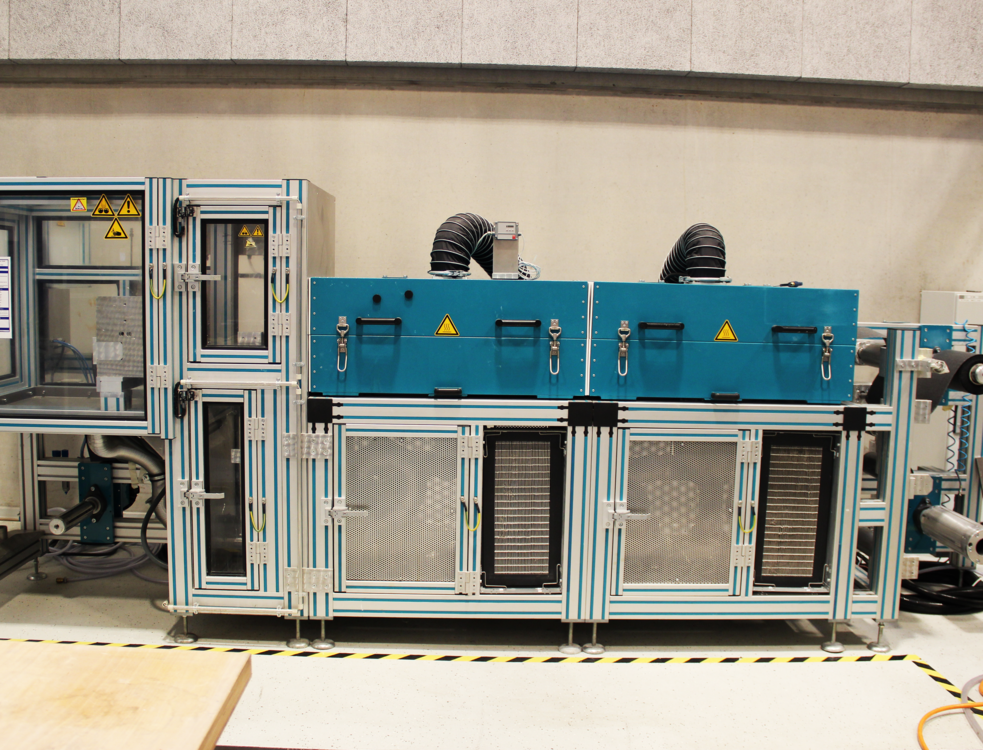

Prepreg system: BaseCoater BC 46 (Coatema Coating Machinery GmbH)

Technical specifications:

- Working width / roller width: 250 mm /300 mm

- Speed: 0,1 - 2 m/min

- Tractive force: 25 - 250 N

- Hot air drying at max. 235°C

- Coating tank volume: 1 litre

Application:

Automated coating machine for the production of pre-impregnated fibre matrix semi-finished products (prepregs). The prepreg production process consists of unwinding, coating, heat treatment (drying and cooling) and winding.

Resin injection plant Tartler GmbH

Technical specifications:

- Processing of up to three components

- Mixing ratios A:B:C up to 1:1:1

- Volume flow / pressure controlled injection process

- Max. Injection pressure: 60 bar

- Material throughput: up to 1 kg/min

- Heating of storage tanks and hose package up to 130 °C

- Measuring systems/sensors: injection pressure, temperatures, mixing ratio

- Process monitoring

Application:

Preheating, dosing and injection of EP or PU resins for the production of FKV or FKV-metal hybrid components by means of a (vacuum-assisted) resin transfer moulding (RTM).

Resin injection plant Wolfangel GmbH

Technical specification:

- Processing of up to three components

- Mixing ratios A:B:C up to 1:1:1

- Pressure-controlled injection process

- Max. Injection pressure: 40 bar

- Material throughput: up to 500 g/min

- Heating of storage tanks and hose package

- up to 120 °C

- Measuring systems/sensors: injection pressure, temperatures, metering ratios

Application:

Preheating, dosing and injection of EP or PU resins for the production of FKV or FKV-metal hybrid components by means of (vacuum-assisted) resin transfer moulding (RTM).

Hydraulic press: LaboPress P200S (Vogt Labormaschinen)

Technical specifications:

- Pressing force infinitely variable (SPS control).

- Pressing force: 1.2-24.5 kN

- Tool plates heatable up to 300 °C

- Cooling of tool plates by means of water/compressed air mixture

- Working area: 200 mm x 200 mm

- Installation height: 175 mm

- Stroke speed: 20 mm/sec (fast speed), 0.5 mm/sec (creep speed)

Application:

The LaboPress P200S is an all-rounder suitable for a wide range of tasks and laboratory applications. Temperature and force control make it suitable for the repeatable production of samples and smaller components, e.g. by means of prepreg pressing.

Servo motorised screw press (Synchropress GmbH)

Technical specifications:

- Maximum pressing force: 300 kN

- Ram speed: 10 mm/s (manual operation), 50 mm/s (automatic operation)

- Working surface: 1200 x 700 mm

- Installation height: 750 mm

Application:

Universal tool testing and production press with high-precision stroke control and optional force control.

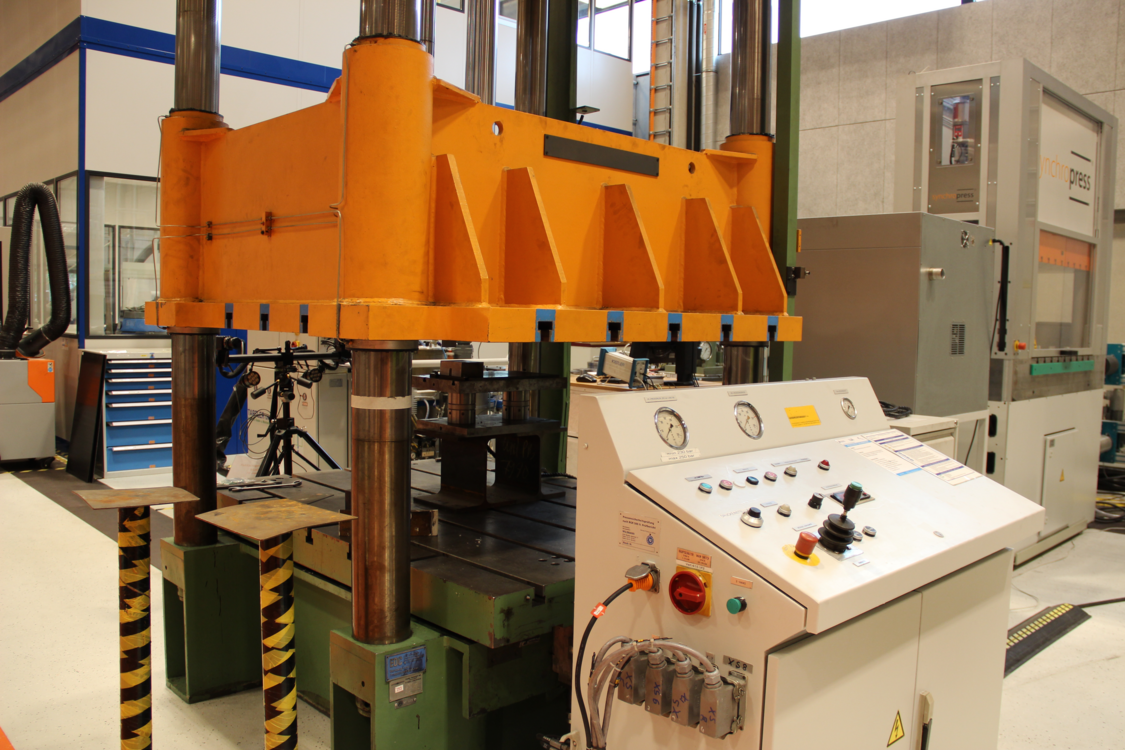

Hydraulic press (Hessmert)

Technical specifications:

- Max. pressing force: 500 kN

- Max. Ram speed: 35 mm/s (upwards), 70 mm/s (downwards)

- Working surface: 1300 mm x 1800 mm

- Installation height: 1600 mm

Application:

All-purpose oil-hydraulic top ram press in column design for carrying out spotting work as well as for producing FKV and FKV-metal hybrid components, e.g. by means of resin injection processes.